From Kilkenny to NY: Textiles crafted at Cushendale Woollen Mills

Six generations of the Cushen family have been crafting textiles in Graiguenamanagh, Co. Kilkenny since the 1700s. Cushendale has recently been involved in several projects showcasing Irish wool yarn on the world stage.

Cushendale's textile journey began in the 18th century with Graiguenamanagh weaver, Sylvester Cushon, and is continued today by Philip Cushen and his daughter Miriam.

Agriland visited the mill and met with Miriam Cushen and her husband Trevor Ging to talk about all things Irish wool, including Cushendale's network of farm suppliers and the transformation from fleece to textile.

Weaving and wool has been an integral part of life in Graiguenamanagh for over 800 years. A woollen mill has operated at the site since 1204 when Cistercian monks founded an abbey.

Monks crafted wool, yarns, and cloth, exporting them to textile centres across Europe. While the buildings have all changed over time, what sustains the link back to 1204 is the mill race, an artificial water channel built by the monks.

Originating from the Duiske River, the mill race once powered the waterwheel. The mill race is a key part of the textile crafting at Cushendale today, Cushen said, with its mountain waters being used for dying and washing textiles.

Miriam Cushen's husband, Trevor Ging works closely with Cushendale's partner farmers, sourcing rare Irish wool, while looking after the business' main customer liaison and logistics.

Cushendale works with three types of wool - Irish wool from the rare and native Galway Sheep, Mohair wool from the hair of the Angora goat, and Merino lambswool.

The family business works with a close network of farmers across eight counties, collecting the fleece of the Galway breed, which is protected in Ireland, directly from farmers every summer.

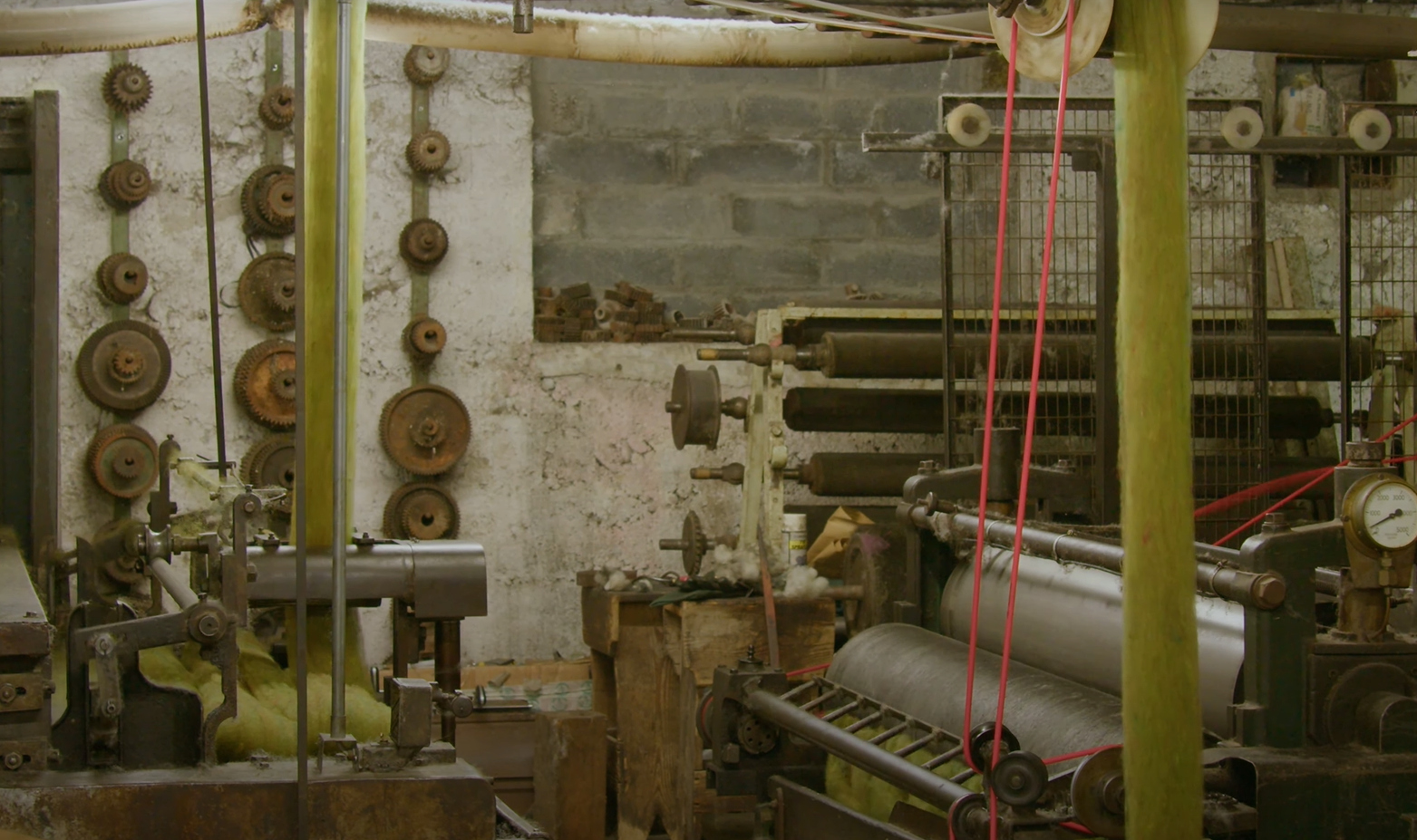

Upon arrival at the mill, the fleece is worked through in small batches before it is washed, teased and dyed. The transformation of the different colours blended together and the initial shape of the yarn becomes visible during the carding process.

The carded wool is then spun on a spinning mule dating back to 1890, transforming the fleece into a strong and durable yarn. In the weaving process, the different colours of yarn create a design and a textile which is then wet and dry finished.

A special characteristic of Cushendale, Cushen said, is that everything is done under its roof. "We shepherd that fleece from when it first arrives here through its transformation into a yarn, into a textile and then into the finished products".

The value of wool over the last 50 years has declined "hugely", Ging said, both in how it is seen and how it is priced. A lot of the emphasis has been on softness, while the value of wool grown in Ireland is in its durability, longevity and function.

"The most important thing going forward is the educational piece, that people are made aware that Irish wool is a great product and it has many positive characteristics, particularly as they relate to sustainability," he said.

Cushendale's Irish wool yarn will feature in a capsule knitwear collection by New York based fashion house Thom Browne, which is due for release later this year and will be entirely produced in Ireland from the wool of the Galway Sheep.

Ging said this project in particular reflects a "very strong endorsement" for the "unique" durability and strength qualities of home-grown native Irish wool.

"In a world where we are trying to move away from fast disposable fashion, more and more brands are now looking to longevity and lifespan of products as another important aspect of sustainability.

"There is certainly a growth potential now for high-quality Irish wool, particularly as it relates to the growing demand to produce longer lasting textiles," Ging told Agriland.

In 2022, Cushendale provided the yarns for the film ‘The Banshees of Inisherin’, with its Irish wool yarn used to create both Brendan Gleeson’s moss and Colin Farrell's wine sweater which, Ging said, is now "iconic".

Last year, the family business provided the wool used in Ireland’s entry for the Venice Architectural Biennale, having prepared and dyed over 1,000kg of Irish fleece which was used to craft a sculpture of Sceilg Mhichíl.