Milking parlour: Is it time to change your liners?

With breeding and silage season in full swing, it can be easy to forget about the maintenance of your milking parlour and to change your liners.

The milk liner is the only part of the milking machine that comes into direct contact with the cow, so the condition of the liner is vital for mastitis control and milking efficiency.

They are expected to last for 2,000 milkings or at least every six months, and should be changed whichever one comes first.

When changing liners, you should ensure that they are installed correctly - failure to do so will result in cows not being milked properly, as the liner might be pay pinch the teat and cause the cow discomfort.

This might also be a good time to fix any other problems that you may have in your parlour - milk line or pulsation tubes should be checked to ensure they are not frayed or damaged.

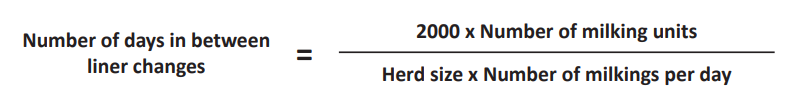

In order to work out how frequently your liners need to be changed, you will need to know the number of cows milking, the number of units the milking parlour is, and the number of milkings/day.

The following calculation can be used to work out the number of days between linear changes:

For instance, if you are milking 140 cows in a 16-unit milking parlour twice a day, liners should be changed every 115 days.

This means that the liners in this parlour need to be changed at least twice a year in a spring calving herd with a two-month dry period.

If this herd started calving at the start of February, liners will have to be changed in the coming few weeks.

Over time, worn liners reduce milking performance, slow down the milking process - which can increase teat end damage and the spread of mastitis-causing bacteria.

As liners wear down, they lose their elasticity and become collapsed, and take longer to open, but will close early as they will collapse under vacuum.

Bacteria can build inside the liner where small cracks form. This roughness can tear the skin of the teat and can be difficult to clean and disinfect.

Changing liners will also reduce the risk of high levels of thermoduric bacteria in your milk as thermoduric will survive in perished rubber.