Sponsored Article

Sponsored Article

Nitrate banding requirements met by supplying slurry to AD plant

Sponsored Article

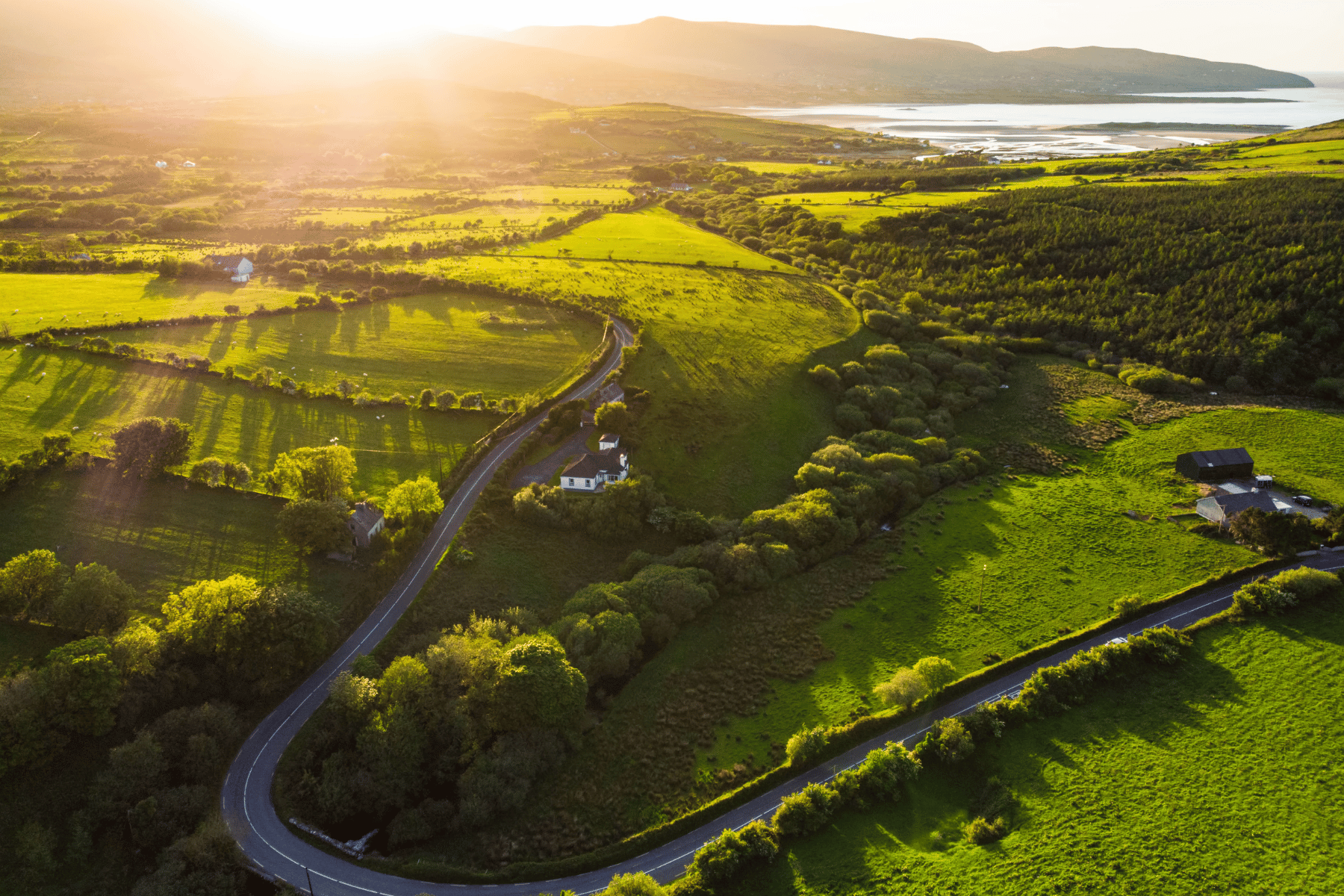

Changes to nitrate banding is just one of the stricter environmental regulations in which farmers are becoming accustomed with as the landscape of Irish farming continues to evolve.

Anaerobic digestion offers an opportunity to manage nitrates in a financially and environmentally responsible way.

Nitrate pollution in Ireland is closely linked to agriculture. It occurs when excess nitrogen from fertilisers and raw animal manure leaches into water bodies.

When nitrates exceed allowable levels, ground water is no longer fit to drink. In surface water, nitrates can cause low oxygen levels, biodiversity loss, algae overgrowth and other environmental concerns.

One need only look at the blue green algae overgrowth that has polluted the waters of Lough Neagh. This alga is present in 60 other locations in Northern Ireland.

Due to the environmental and health concerns around nitrate pollution, Irish farmers are under increasing pressure to reduce nitrate runoff and comply with Ireland’s Nitrates Directive, which limits farmers to the Ireland’s Nitrates Directive, which limits farmers to 250kg of livestock manure per hectare annually.

Irish farmers have also recently seen the Nitrates Derogation allowance reduced to 220kg/ha and another amendment is on the horizon.

ReNure is a proposed amendment that seeks to facilitate the reuse of organic nutrients by using anaerobic digestate (digestate) as fertiliser.

Under this scheme, farms would be allowed to import an additional 100kg/ha of nitrogen in the form of digestate from an anaerobic digestion (AD) plant which would be offset against their annual fertiliser allowance of 250kg/ha.

This additional nitrate allowance is just one of the potential benefits of anaerobic digestion for Irish farmers.

Biomethane producers like CycleØ offer farmers long-term partnership opportunities to supply their animal slurry as feedstock for AD plants.

Slurry partners simply transport their animal manure to a nearby AD plant instead of having to reduce herd stocking rates, build expensive storage facilities, or buy or lease additional land to spread slurry in compliance with nitrate regulations.

This can lead to significant cost savings on storage and transportation, while maintaining productivity by keeping the same herd size.

Digestate, a nutrient-rich by-product of AD, offers farmers additional benefits as a source of low-cost fertiliser that can also reduce nitrate pollution.

Unlike chemical fertilisers, digestate is locally produced and not subject to volatile global market shifts. It also contains nitrogen that’s easier for plants to absorb than synthetic fertiliser, reducing the risk of excess nitrates entering water bodies.

Ammoniacal stripping is an optional component of the biomethane production process that removes nitrogen from the digestate, so farmers can potentially apply it to crops to ensure maximum uptake and productivity.

This technology has already been successfully deployed in Spain by CycleØ.

In summary, AD and biomethane production deliver a sustainable, trustworthy and economically sound way to cut waste management costs and support decarbonisation. Here’s how:

- Lower waste management complexity and costs – Farmers can avoid herd stocking reductions, building expensive storage infrastructure, and buying or leasing additional land to spread slurry so they can comply with nitrate regulations. Instead, slurry partners can simply transport animal manure to a nearby AD plant.

- Reduce nitrate pollution – The nitrogen in digestate is easier for plants to absorb than that of synthetic fertiliser, which reduces the risk of excess nitrates entering nearby waterways. Ammoniacal stripping, an optional part of the biomethane production process, removes nitrogen from digestate so farmers can apply it selectively to maximise uptake.

- Promote a circular economy – By transforming animal slurry into digestate, farmers can implement a circular economy. This practice minimises waste, maximises resources and returns valuable nutrients to the soil, which can improve crop health and productivity. As digestate is locally produced, it’s also not subject to the volatile global market shifts that affect the price and availability of synthetic fertilisers.

- Meet decarbonisation targets – Farmers are increasingly being asked to decarbonise their operations. AD and digestate can help. Replacing ~1t of synthetic fertilisers with digestate can keep the equivalent of ~4t of carbon from entering the atmosphere. That’s equivalent to eliminating ~20% of Ireland’s annual carbon dioxide emissions.

Discover how partnering with CycleØ as a slurry partner can simplify compliance with nitrate regulations and make your farm more sustainable.

Sponsored Article