The genius of Norman's articulated MF 35

Sometimes, just restoring a tractor is not good enough for a creative mind - the project has to be taken further, much further, until a true masterpiece of engineering is turned out that defies logic and maybe sense, but at the same time is tremendous fun.

Such is the articulated Massey Ferguson 135 built by Co. Kerry farmer Norman.

Wherever the tractor goes, it draws tremendous interest and rightly so.

But beneath its impressive looks and sheer presence, Norman has, in a way, posed some serious questions about the evolution of the tractor in the middle of the 20th century, and from that perspective his articulated MF 35 should be considered art as much as engineering.

However, it is the engineering that really stands out, with the basic concept being one that is particularly rare, maybe even unique to the tractor world.

Whereas most articulated four-wheel drive conversions have either linked two tractors together - in the manner of the Doe Triple D - or added a second driven axle to a skid unit along the lines of the MF 1200, Norman has taken a different approach altogether.

In this creation, he has taken two MF rear axle assemblies and placed them end to end facing each other, meaning that while the back half is as a standard tractor, the axle at the front has been reversed and, in effect, drives backwards.

It is in many ways a brilliant solution to answering the quest for equal-sized four-wheel drive, and it has to be wondered why this approach was not taken before by specialist manufacturers.

Back in the 1960s and 1970s, the emphasis was on adding a third party front axle to a skid unit - County Tractors and Muir Hill being the classic examples.

Looking at Norman's tractor, that approach now seems rather clumsy and rushed. It was probably considered the sensible thing to do at the time but lacks any great thought about the problem, or maybe it was just too radical for the era.

Yet Norma's arrangement works beautifully, or at least he has got it to work in this one-of-a-kind example put together in a farm workshop, and that takes a certain amount of genius.

The secret lies in reversing the drive to the front unit, and this, Norman insists, will remain a secret for so long as the tractor remains with him. But should he sell it, then of course it will become public knowledge.

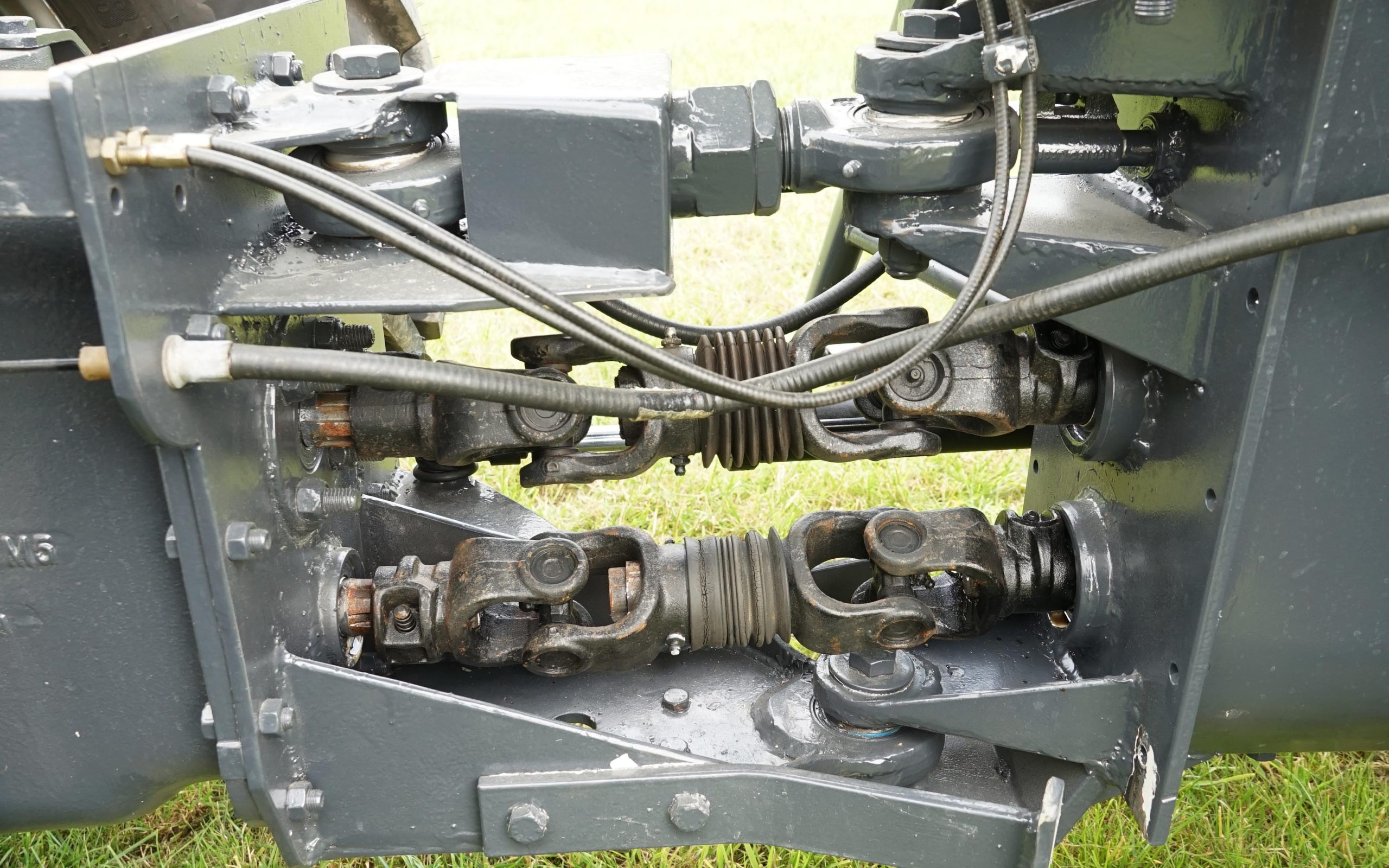

What can be said however is that drive from the engine is fed to a standard gearbox. Then from the output shaft, it is taken down by chain to the two transmission tunnels, with four-wheel drive being activated by engaging the front axle.

Norman will disclose little more than that about what goes on inside the transfer box he fabricated to contain the chain drive and gearing, but he has also managed to retain the power take-off (PTO), which is still operated from the driver's seat.

Indeed, all the tractor tractor functions remain, including the hydraulics and three point linkage, and in the case of the brakes, they are actually enhanced.

The brake pedal is connected by rod to the forward axle to operate the brakes at the front. A further rod and Bowden cable connects this front lever to the rear, the cable being a necessity to solve the issue of bridging the hinge point between front and rear.

Now that all four wheels are braked, the overall effect is a huge improvement on the original set-up - stopping the tractor is no longer a matter of long-term planning.

The rear linkage is still functional. Before its final coat of paint, Norman tried it out with a plough and it performed to his great satisfaction with great traction, providing far more traction than the 44hp Perkins P3 could utilise.

This was helped by the 13.6-28 tyres, which are larger than the original but do look the part and add immeasurably to the appearance of the machine. The narrower originals just would not look right.

MF Construction yellow is the colour of choice - again, it looks right and the famous red livery would have reduced the drama of the tractor's presence, Norman said he wanted it to stand out, and it does that with a radiant panache.

On the face of it, there would have been two great objections back in the time to such a machine being produced commercially.

The first is of course cost, but a County would be twice the price of its donor Ford skid unit so that might not have been quite so prohibitive.

The second is height - placing the engine, and then the cab over a bulky transmission increases this dimension considerably. Yet the Muir Hill was a lofty tractor and Norman is familiar with the marque, as the family had them on the farm at the time.

Perhaps then it was a lack of imagination or technical ability, or maybe the demand for four-wheel drive was not so strong when power ratings were generally well below 100hp.

Yet here we have living proof that equal-sized four-wheel drive was quite possible without the need to buy in large specialist components like driven axles.

Massey Ferguson did go on to make the the 1200 using standard parts and yet, despite the intelligence of the idea, it never really caught on.

The farmer, it seemed, was wedded to the standard tractor format with four-wheel drive being considered a little exotic and very expensive, it took Zetor to lead the way out of that particular cul-de-sac.

Norman spent five years creating this tractor, he has a lifetime's experience of fixing and maintaining machinery.

This experience came first from the family plant hire business up until the first inklings that the boom was about to go bust 20 years ago.

Since then, Norman has kept himself busy restoring tractors, including many small Massey Fergusons. Hence he could draw on his own experience and a large number of spares he has lying around.

He also received a good deal of assistance from Ned Murphy Tractors and Clifford's tractor parts during the years he spent working it all out and putting it together.