Vogelsang launches mobile XSplit slurry separator

It is perhaps Ireland's worst kept agricultural secret, that there is hardly the capacity to store the slurry produced by the national dairy herd.

The rapid expansion of herds has often left the storage facilities behind, with farmers desperate to make room in their tanks just as soon the the deadline in their area is reached.

This often means that tractors and tankers will be sent to the field long before ground conditions are suitable, especially in wet springs as we have experienced this year.

Fundamentally, there are two different ways to manage this situation.

The first is to build more, expensive storage, while the second is to separate the solids from the water and so reduce the overall volume of material that needs to be kept in the tanks.

The idea is far from new and the practice is well understood and utilised on the continent, and has been for many years.

In Ireland, the idea is slowly catching on with all the major slurry equipment manufacturers offering to install separation systems based on the particular pumps and separators they sell.

These, however, are all fixed systems and so, generally speaking, there is one separator to a tank, which can be expensive for farms with multiple lagoons, or a rather too large investment for a small farm with only limited use for this type of machine.

One answer to this conundrum is to share the press with other farms through the use of a mobile separator.

Again, this is something that is common on the continent, but the concept is now available in Ireland thanks to Vogelsang's new mobile unit.

Taking a separator to farms makes a good deal of sense, for it will spread the cost of the machine around the holdings and makes itself a worthwhile new service for contractors to offer at times of the year when they may well not have much work on otherwise.

Vogelsang has been touring the UK and Ireland with a demonstration unit for the past couple of years.

It has now taken the concept one step further, by designing and building a purpose-made trailer unit that is intended as a mobile working separator that has already found a contractor customer in Munster.

Rather than adapting a standard flat bed trailer, this new product is made by Vogelsang from the ground up to purposefully fill a role which it sees as a potential new market, further expanding its product range in doing so.

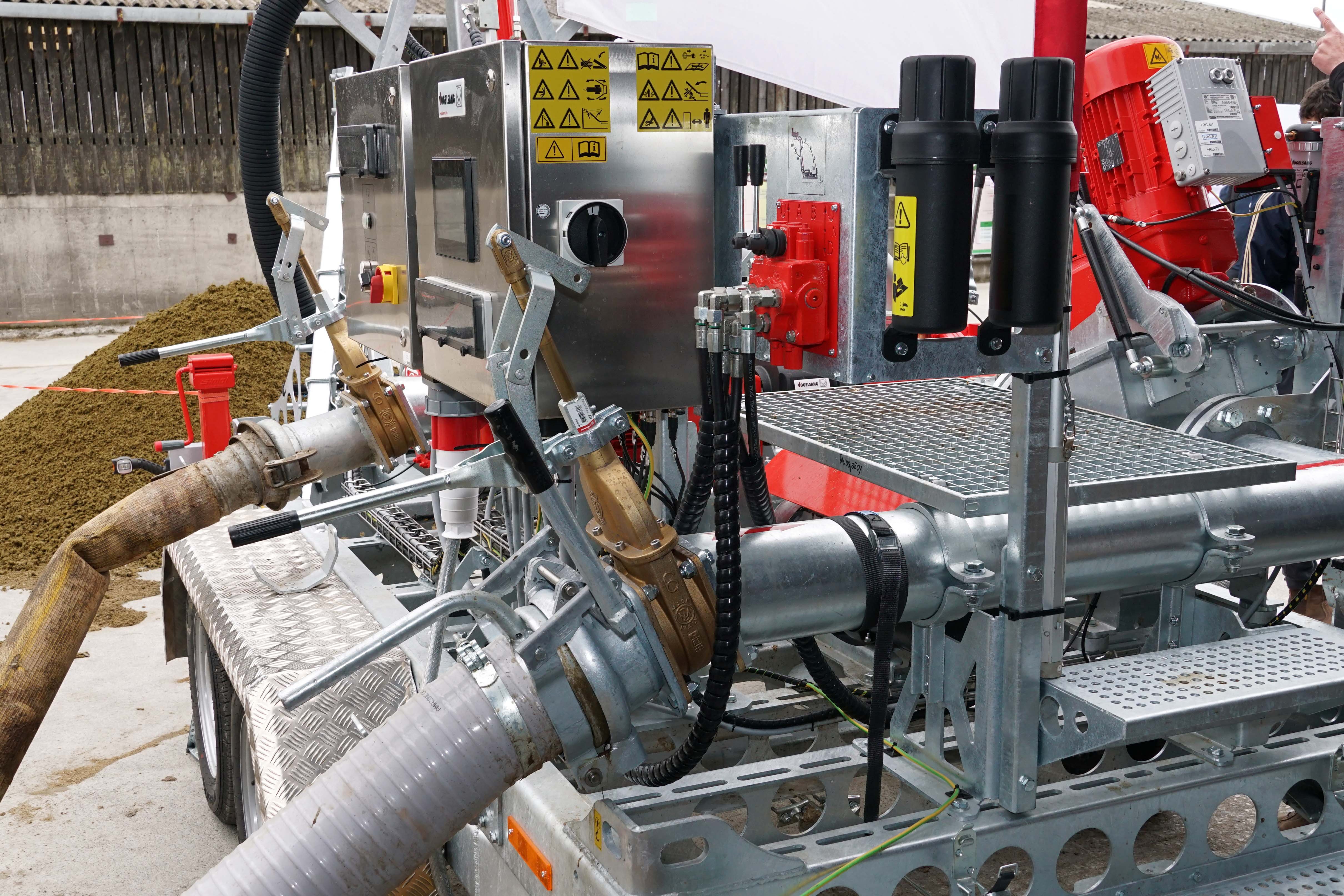

The trailer itself has no deck, it is now a purpose-built galvanised frame with the various components bolted to it.

This arrangement has two major advantages - first, it makes cleaning a great deal easier as any residue can be hosed off with it falling directly on to the ground rather than accumulating on a flat deck.

The second is that it makes for a more rigid structure that sits between the wheels rather than above them, lowering the centre of gravity and increasing towing stability in doing so.

The all-up weight is just under 3,500kg, making it towable between jobs behind a pick-up or van at legal road speeds.

There are stowage racks attached for both rigid suction pipes and lay-flat discharge hoses.

There are four major fluid handling components to the unit, plus an additional boom that raises the height of the discharge to accommodate larger trailers, plus a control panel.

These four items are arranged so that the slurry is drawn from the tank or lagoon through a combined macerator and stone trap, known as a rotorcut, by the first positive displacement lobe pump.

The pump can draw liquid from 3m and having pulled it through the rotorcut, it sends the now more consistent fluid to the XSplit separator itself, which sits upon its own boom that is raised hydraulically for trailer loading.

Vogelsang claims that the XSplit unit can produce material of up to 40% dry matter (DM), leaving the liquid faction to return to the discharge pump which can return the fluid to a second tank by lay-flat hose.

All the motors are three phase, so the unit will require a suitable electricity supply, if none is available a 50kW generator is recommended to power it.

Vogelsang appears to have created a well thought-out and robust unit that will enable the benefits of slurry separation to be brought to many farms that would otherwise be unable to afford the ability to reduce the liquid slurry that needs to be stored.

Much larger, lorry-mounted units are available on the continent, but the beauty of this design is that it is small, lightweight and easily transportable, making it suitable for more modest-sized farms which need a hand to get through the winter, rather than be an integral part of their slurry management system.